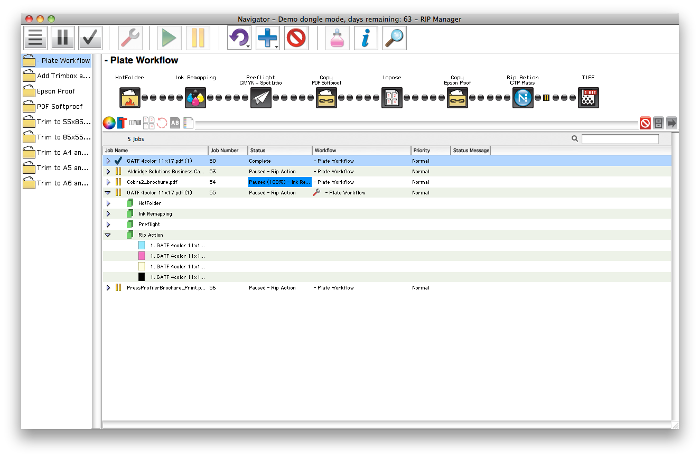

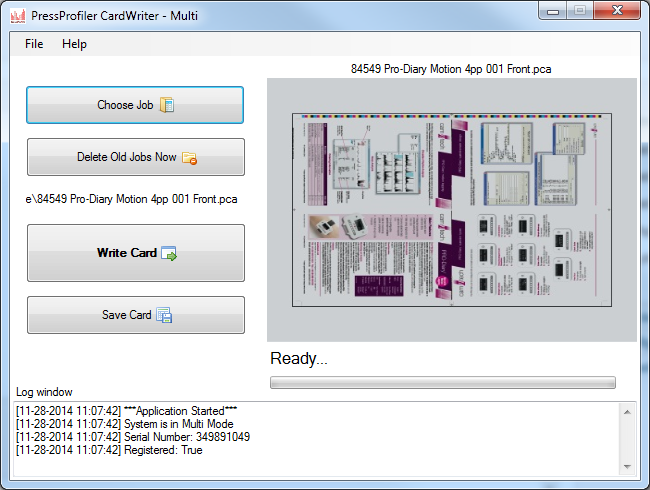

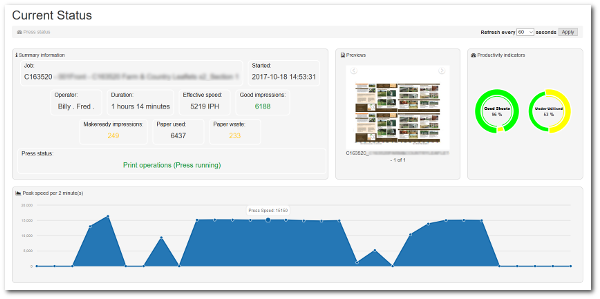

PressProfiler CIP3 Links to both Heidelberg and Komori presses for Baesman Group

The latest success in the United States for UK-based software supplier Prepress UK has been with Ohio-based Baesman. The installation of Prepress UK’s leading press interface product, PressProfiler CIP3, initially helped the marketing communications group to get the most from its Heidelberg XL105 litho press, and has more recently also enabled the printing team to

continue reading...